Revolutionary Production of Metal Powder for Additive Manufacturing

WHY WE ARE DIFFERENT

UniMelt is spheroidization NOT atomization – changing the way metal powder is produced

The only sustainable, high-quality metal powder producer using sustainable feedstock

Watch video to learn more about why we are different

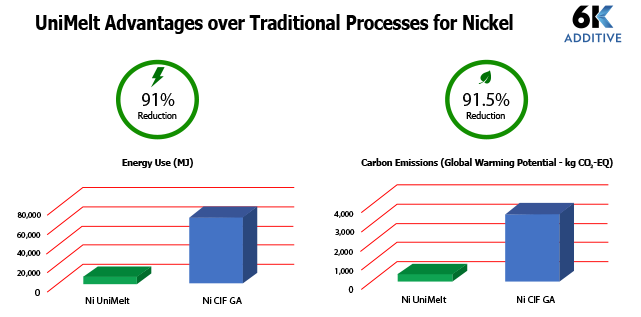

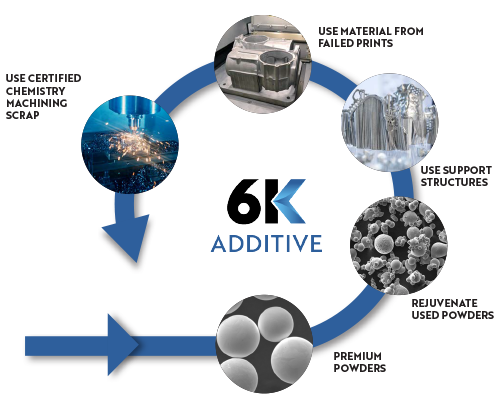

RECLAIMED FEEDSTOCK AND EFFICIENT PRODUCTION IS KEY TO SUSTAINABILITY

We upcycle used powder and revert into high-value metal powder for AM

DRIVING THE CIRCULAR ECONOMY

HIGH PERFORMING POWDERS BACKED BY STRINGENT QUALITY CONTROL

High quality metal powders for AM at production scale

Highly spherical powders – void of porosity and satellites, fully dense with no gas entrapment offering better flowability than any other powder manufacturing process.

COMPREHENSIVE POWDER TEST & QC

Rigorous quality control with extensive in-house analytical capabilities including micro-CT, gas analysis, ICP, XRD, SEM, EDS

PART PRODUCTION & TESTING

Meeting or exceeding ASTM and ASM standards verified by leading AM industry experts, partners and customers

POWDER TRACKING & PREPARATION

Industry-standard methods for powder blending, lot control and packaging

“The lab tested five samples, and each one returned density results of 99.9%, which far exceeds the minimum requirement. Anything over 99.5% density in additive manufacturing is a good part.”

Kevin Engel

Want to Learn More About Our Metal Powders?

EXPORT CONTROLLED

Products, technical data, technology and services of 6K Additive Products are subject to U.S. export controls under the Export Administration Regulations and the International Traffic in Arms Regulations. Products, data and technology may not be resold, diverted, transferred, transshipped, made available to a foreign national within the United States, or otherwise disposed of in any other country outside of its intended destination, either in its original form or after being incorporated into other products or data without the prior written approval of 6K Additive. In addition, products, data and technology may not be exported or re-exported to entities or persons that are ineligible under U.S. law to receive U.S. products and technology.