UniMelt Microwave-Based Plasma Technology

Breaking Traditional Barriers – Collapsing Days to Seconds.

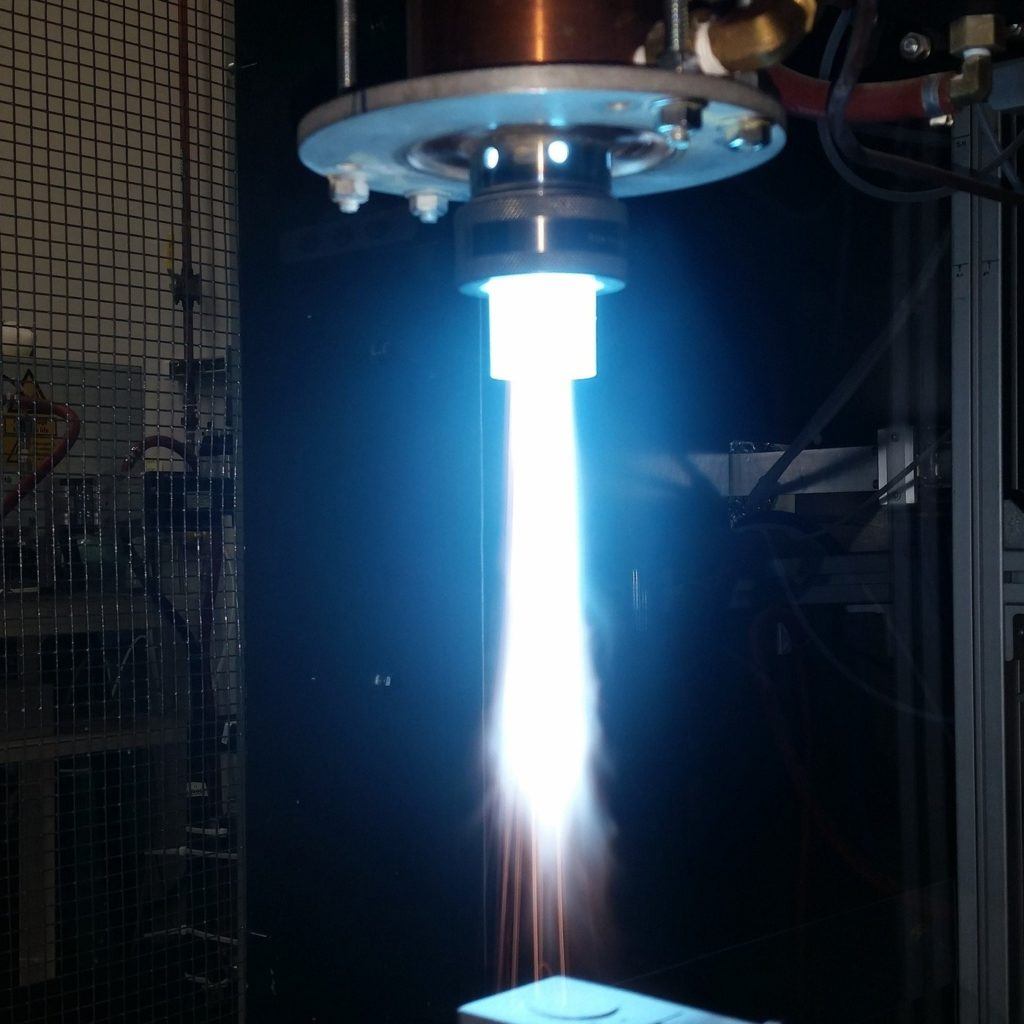

The most advanced production plasma system in the world is here. Meet UniMelt® – Uniform Melt State Process. 6K’s proprietary process technology is based on high-frequency microwave plasma.

Introduction to UniMelt

6K’s proprietary UniMelt® system is a production-scale microwave plasma process that produces advanced materials used in additive manufacturing, battery material and other industrial markets with a process that is fast and environmentally friendly. For additive manufacturing the UniMelt process precisely spheroidizes metal powders while controlling the chemistry and porosity of the final product. For battery material, the same sustainable process is used to synthesize chemical elements and control particle size and microstructure to produce advanced battery material at a fraction of the time and cost as conventional processes.

In Less Than 2 seconds.

That’s the typical time to produce a material in 6K’s system from start to finish. 1/100,000th the time of traditional chemical or solid-state production technologies today.

Conventional chemical and solid-state production processes for advanced materials are multi-step, batch-to-batch, with contaminants and yield loss at every step. And they often take hours or even days to complete.

6K’s UniMelt® process is a continuous flow operation, a single step from start to finish. In less than 2 seconds.

How?

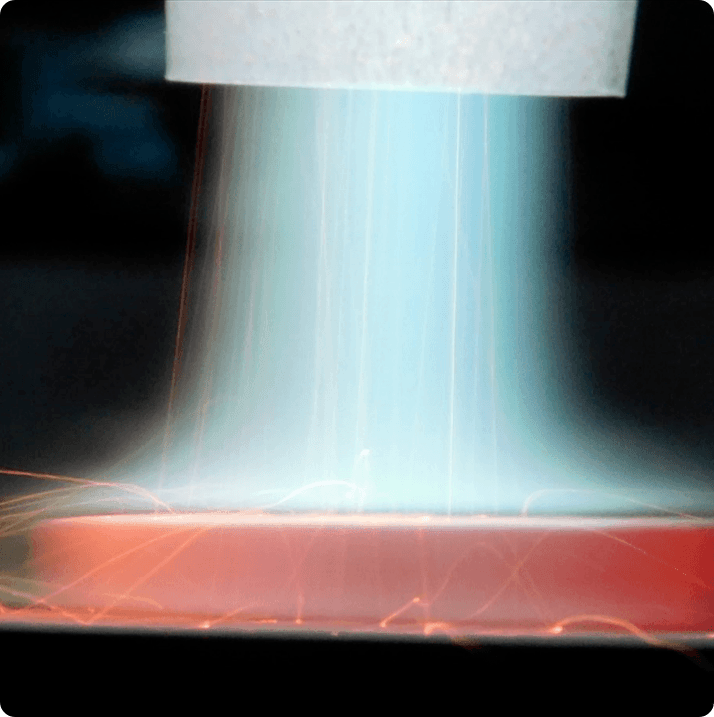

6K pushes past what is possible with conventional chemistry by exploiting the physics of plasma chemistry. A combination of high heat, highly reactive ions, and designed chemistries create the perfect environment to collapse processes into previously unattainable periods of time.

Not like any other plasma

6K has the world’s only production-scale microwave-based plasma, supported by 126 patents and counting.

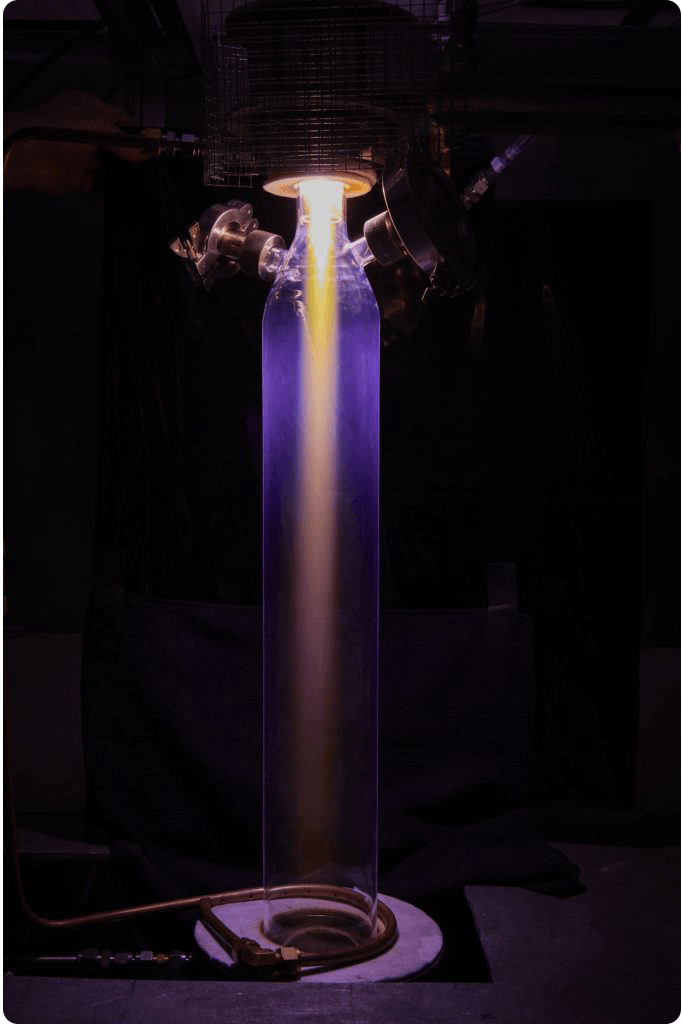

Production of advanced materials at high volumes with tight specifications requires technology with high throughput and extremely uniform process conditions.

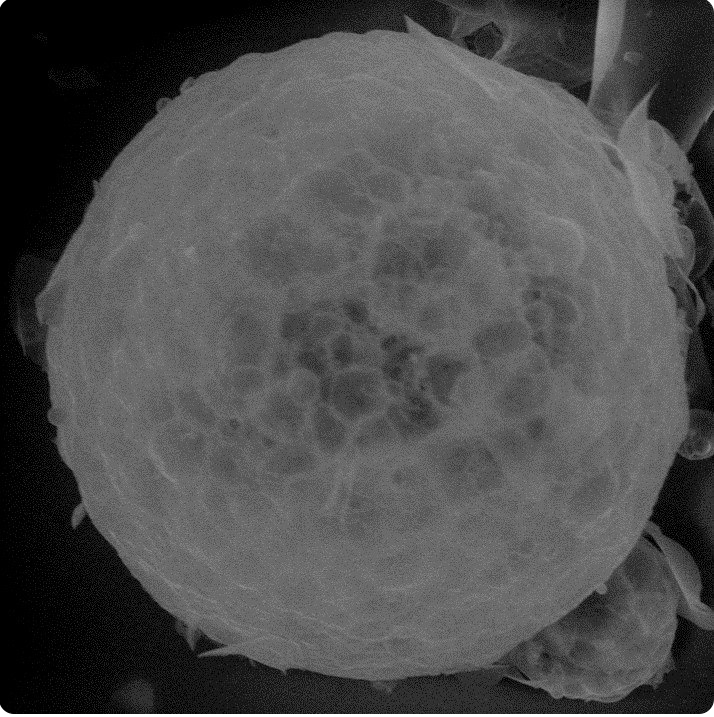

The ability to precisely synthesize and tailor an unlimited spectrum of oxides, nitrides, metals & alloys derives from the ability to control all aspects of the plasma process flow. Microwave-engineered plasma provides a thermal production zone of extreme uniformity, guaranteeing every particle sees the same thermal kinetics and the same process history.

The same technology enables a large production zone, scalable to 100+ tons/unit/year, and 99% microwave coupling efficiency – translating to higher throughput and lower cost.

The most versatile production platform

It can create complicated materials with tight specifications in seconds.

6K’s platform technology is tailorable for synthesizing nano and micron-sized powders, spheroidizing, and densifying metal and ceramic powders, as well as depositing these materials on targeted substrates through plasma spray deposition.