6K Energy Production Facilities

6K Energy Battery Material Production Plans Start with PlusCAM™

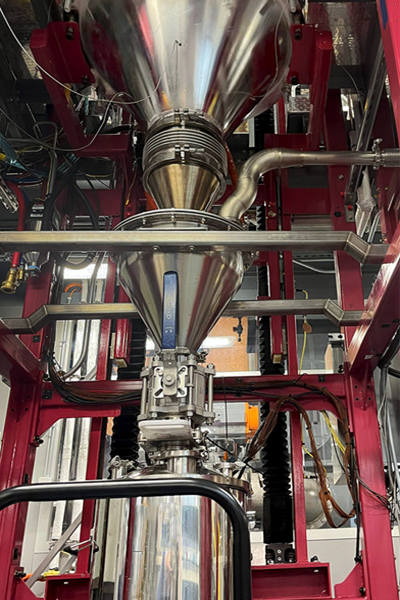

PlusCAM™ the World’s First Plasma Cathode Plant

PlusCAM factory will be a full-scale battery material manufacturing plant in Jackson, Tennessee, providing low-cost, ultra-sustainable production of battery material for localized supply chains in the US. This plant will be the first in a series of multi-chemistry plants providing a blueprint to replicate easily.

Key Initiatives for PlusCAM include:

Sustainability Initiatives

Diversity and Inclusion Initiatives

PlusCAM – providing low-cost, ultra-sustainable production of battery material.

6K Energy Battery Center of Excellence (BCE)

6K Energy’s State-of-the-Art Battery Material Development Facility

6K Energy’s Battery Center of Excellence focuses on the development of battery material production in the United States. This 33,000 sq ft state-of-the-art facility works closely with battery cell manufacturers, OEMs, and recycling partners to develop the next generation of sustainable battery material production for electric vehicles, grid storage, and consumer goods. This facility supports the full-scale development of materials such as high energy density and single crystal cathode, solid-state electrolyte materials, and Silicon Anode, to name a few.

The Battery Center of Excellence fully supports partner qualification of new materials, offering dedicated UniMelt systems to customers, enabling the rapid commercialization of battery materials.

Key Initiatives for the Battery Center of Excellence:

6K Energy’s BCE – developing a sustainable production process for the next generation of battery material.

Sustainable Battery Material Production

Faster – Cleaner – Lower Cost

Infinite Battery Material

Learn about our production roadmap

UniMelt Technology

Transforming manufacturing with microwave plasma