Advance CMP Materials For Semiconductors Process

Polishing Materials for Demanding Applications

6K’s UniMelt® for Chemical Mechanical Planarization (CMP) polishing materials is a proprietary plasma manufacturing process that reduces traditional constraints on available source material & supply chain challenges; improves purity, tailorability, cost, and improves defect control. 6K’s CMP materials remove unwanted conductive or dielectric materials on the silicon wafer, achieving a near-perfect flat and smooth surface upon which layers of integrated circuitry are built.

6K can create and tailor material specifications for semiconductor CMP applications:

- Synthesize or process many families of materials: Alumina, Ceria, and Coated Silica Particles

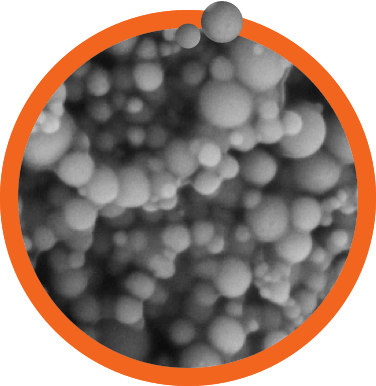

- Tightly control powder size (10nm – 100 micron) and powder size distribution, phase, morphology, and charge

- Create nonsurfactant based – non-agglomerated dispersions for next-generation wafer production

- Create 100% dense spherical powders with high uniformity – nonangular – no defect polishing

Premium Powders for Advanced Applications

Semiconductor applications have demanding and diverse requirements. 6K’s UniMelt® technology can be used to create Alumina, Silica, and Ceria based materials, as well as specialty particle coatings for CMP applications with tailored characteristics.

Characteristics inherent in powders processed in UniMelt® include high sphericity (no edges), no satellites, tight powder size distribution (no oversized particles), non-agglomerated, highly dispersed and within specified Zeta Curve parameters.

Oversized and angular powders can be a real issue in CMP applications where defects can compromise the operation of the semiconductor. Unlike fumed or batch chemical processes, the UniMelt® process does not produce angular powders during processing, and can actually densify powders, making them more efficient in their planarization.

Enabling New Business Through Partnership

We provide our strategic partners with higher quality materials for demanding applications, and the opportunity to engage in new business models:

- Premium abrasive powders in dispersion from qualified raw material sources

- Direct vertical integration on the semiconductor manufacturing value chain within a strategic partnership

- New material and application-specific joint development

- 6K is working with strategic partners across various markets and industries – learn more about our partnership opportunities