REDEFINING CRITICAL MATERIAL MANUFACTURING DRIVING TOWARDS A SUSTAINABLE FUTURE

UNIMELT®

Plasma Technology

6K's UniMelt enables a new era of sustainable manufacturing

UNIMELT®

Plasma Technology

6K's UniMelt enables a new era of sustainable manufacturing

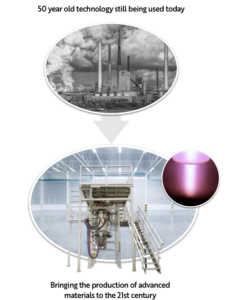

Transforming Legacy Industrial Production with High Efficiency Plasma Technology

Replace outdated dirty process technologies with clean, efficient production

- Highly engineered products

- 2 second production vs 2 day

- 50%-90% lower cost

- Scalable, small production footprint

- Infinite performance material options

The World’s only Sustainable Production for Advanced Materials

Clean technology is clean… isn’t it?

By 2030, electric vehicles will consume 1000 GWh of battery production per year… And create massive waste and GHG.

6K solves this problem by lowering greenhouse gases, energy and water consumption.

Reduce 70% of CO2 GHG = 40 billion pounds

Reduce 70% of CO2 GHG = 40 billion pounds

Reduce 100% of wastewater = 203 billion liters

Reduce 100% of wastewater = 203 billion liters

Reduce 90% of water use = 188 billion liters

Reduce 90% of water use = 188 billion liters

Reduce 70% of energy use = 26 billion kWh

Reduce 70% of energy use = 26 billion kWh

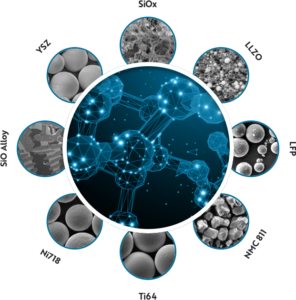

Pioneer Today, Enable Tomorrow: 6k Brings Infinite Material Possibilities

Meeting the world’s future needs for materials: UniMelt microwave plasma breaks the rules

- Previously unattainable design flexibility

- From nanometers to microns: 10,000 x size

- Metals, alloys, oxides, silicon, carbides, nitrides & more

- Hollow, dense, nano-foam, single crystal, transparent, meta-stable, intermetallic composite & more

Their Scrap is Our Feedstock: Creating A Circular Economy

Paving the way for domestic performance material manufacturing independence

- Access to infinite supplies of scrap metals, used batteries and powders

- Local and on shore production from domestic feedstock

- Address national security of critical materials

- Reduce mining of scarce minerals

- Support local circular economy ecosystems

6K reduces dependence on foreign materials and ensures supply chain integrity by unlocking domestic supplies of feedstock

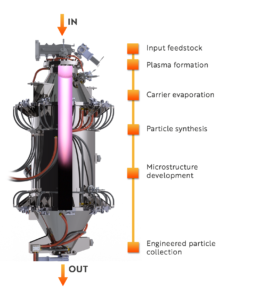

Unimelt Plasma:

How Does it work?

UniMelt Plasma is proven high volume production system for performance materials

- Digital process control

- 6,000 degree operations (6K)

- 99% efficiency (microwave to plasma)

- Under 2 second production time

- 99.999% contamination free