6K Additive to Increase Metal Alloys Offering with the Acquisition of Specialty Metallurgical Products

Strategic acquisition expands product portfolio for metal alloys business for aerospace, automotive and medical industries

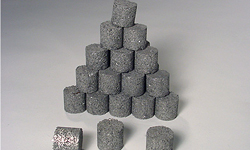

Burgettstown, PA. October 13, 2021 – 6K Additive a division of 6K, the leader in the production of sustainable advanced materials for energy storage, additive manufacturing powders and metal alloying additives today announced it has acquired Specialty Metallurgical Products (SMP) based in Red Lion, Pennsylvania. SMP specializes in titanium and zirconium tablets used as a grain refinery for the metal alloys market. The acquisition augments 6K Additive’s existing line of Ty-Gem compacts used in similar applications and markets. The new product enables 6K Additive to expand commercial relationships into both new and existing companies for titanium customers while developing new applications and customers for zirconium additives. The acquisition further solidifies 6K Additive as the premier supplier of metal alloying additives to primary and secondary aluminum producers worldwide. The terms of the acquisition were not disclosed.

Frank Roberts, President of 6K Additive commented, “We have over 20 years of experience supplying our Ty-Gem grain refining products to the aluminum industry. Adding SMP’s titanium products to our portfolio will complement our existing offering while enhancing our expertise in the process. The acquisition will also add an entire new product line to our current portfolio in zirconium tablets. The quality products SMP brings to 6K Additive enables us to go broader and deeper with our customers providing a quality, sustainable alloying solution no other company in the world can offer.”

“We have a long history of supplying the top end of titanium additives to the industry and have established SMP as the leading supplier of zirconium,” said Jim Clark former President of SMP and now strategic advisor of 6K Additive. “Becoming part of the 6K Additive team ensures our customers are provided with the same quality product, but backed by a larger organization that has the logistics and operational infrastructure to support our rapid growth.”

6K Additive employs proprietary technology to recycle titanium scrap from machining operations into essential inputs for metal alloys. 6K Additive has over 20 years of experience supplying Ty-Gem compacts to the aluminum industry with the capability of processing over 3 million pounds of titanium scrap that directly contributes to over 3 billion pounds of aluminum at primary and secondary aluminum producers worldwide.

6K Additive is also the premium supplier for 3D printing metal powder that is produced from sustainable sources, targeting the commercial aerospace, medical, and industrial sectors. Following the commissioning of its 45-acre ISO9001 24/7 state-of-the-art powder production operations in 2020, 6K will now expand production with an additional 600 tons/year and set up sales and distribution in Europe and Asia.

###

6K represents 6000 degrees, setting 6K technology apart from all others. It is the temperature of operation of our UniMelt® system, the world’s only production-scale microwave plasma system, and is also the temperature of the surface of the sun.

6K uses proprietary advanced plasma processing and industrial systems to create materials that are enabling the next generation of commercial and consumer products. The company’s continuous UniMelt process allows for complete and unprecedented control of the entire materials engineering process, to produce materials at exact specifications at lower cost from sustainable sources.

The 6K Additive division is an ISO9001 facility, reclaims and processes over a million pounds of Ti64 per year, and has recently built and commissioned a state-of-the-art 48,000 square foot production facility for additive manufacturing powders.

To learn more about 6K, please visit www.6Kinc.com