Titanium Alloy Powder – Ti6Al4V

Titanium Alloy Powder for Additive Manufacturing

HIGH-PERFORMANCE PARTS START WITH HIGH-QUALITY METAL POWDER

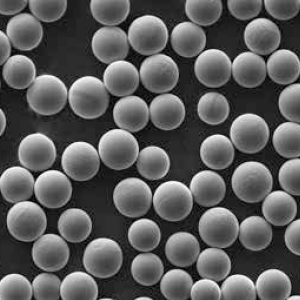

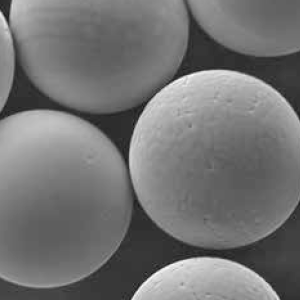

6k Additive Ti6Al4V Titanium metal powder for additive manufacturing. Ti6Al4V Titanium is a high-strength, low-density Ti alloy known for its excellent corrosion resistance. 6k Additive’s Ti6Al4V spherical metal powders deliver excellent material properties that enable AM 3D metal print designers to take advantage of the design freedom of additive manufacturing Titanium metal powder.

Ti6Al4V is a heat treatable α-β Ti alloy. The biocompatible properties make Titanium Ti6Al4V powder ideal for medical implants as well as applications in aerospace, automotive, and industrial. Due to its high strength-to-weight ratio, Ti6Al4V metal powder is particularly attractive for additive manufacturers in automotive and aerospace applications providing design flexibility through material innovation.

6k Additive Ti6Al4V metal powder is available in two grades – Grade 5 and Grade 23 (ELI). It is also available in a variety of sizes and we can customize the PSD of our Titanium alloy metal powder to the state you are looking for.

6K Additive Ti6Al4V Powders

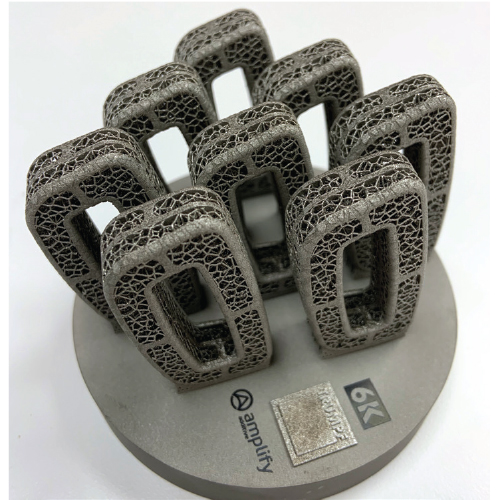

Spinal cages designed and printed at Amplify Additive on a Trumpf TruPrint 1000 LPBF system with 6K Additive’s Ti6Al4V metal powder.

LCA Titanium Metal Powder Life Cycle Assessment Report

Foresight Management completes first-ever LCA for AM powder manufacturing processes for titanium metal powder production.

Ti6Al4V Metal Powders Specifications

| Nominal Chemistry | ||

|---|---|---|

| Grade 5 | Grade 23 | |

| Titanium | Balance | Balance |

| Aluminum | 5.5-6.75% | 5.5-6.5% |

| Vanadium | 3.5-4.5% | 3.5-4.5% |

| Iron (Max) | 0.40% | 0.25% |

| Oxygen (Max) | 0.20% | 0.13% |

| Carbon (Max) | 0.08% | 0.08% |

| Nitrogen (Max) | 0.05% | 0.03% |

| Hydrogen (Max) | 0.015% | 0.012% |

| physical properties | |

|---|---|

| 15-45 μm | |

| Apparent Density | 2.3 g/cm3 |

| Tap Density | 2.8 g/cm3 |

| Hall Flow | 26 s/50g |

| tensile Properties | |||||

|---|---|---|---|---|---|

| Powder | YS (MPa) | UTS (MPa) | EL (%) | RA (%) | |

| XY | 6K (HIP) | 909 | 999 | 18 | 41 |

| XY | ASTM F3001 | 795 | 860 | 10 | 25 |

| Z | 6K (HIP) | 905 | 979 | 19 | 46 |

| Z | ASTM F3001 | 795 | 860 | 10 | 25 |

EXPORT CONTROLLED

Products, technical data, technology, and services of 6K Additive Products are subject to U.S. export controls under the Export Administration Regulations and the International Traffic in Arms Regulations. Products, data, and technology may not be resold, diverted, transferred, transshipped, made available to a foreign national within the United States, or otherwise disposed of in any other country outside of its intended destination, either in its original form or after being incorporated into other products or data without the prior written approval of 6K Additive. In addition, products, data, and technology may not be exported or re-exported to entities or persons that are ineligible under U.S. law to receive U.S. products and technology.